Fiber Laser Cutting VS. CO2 Laser Cutting: The Differences

With the development and upgrading of laser technology, laser equipment is also updated with iterations. The pace of new equipment replacing old equipment and becoming the new mainstream in the manufacturing industry is accelerating. Why can fiber laser cutting replace CO2 laser cutting and become the "new darling" of the manufacturing industry? This article analyzes it from the following aspects.

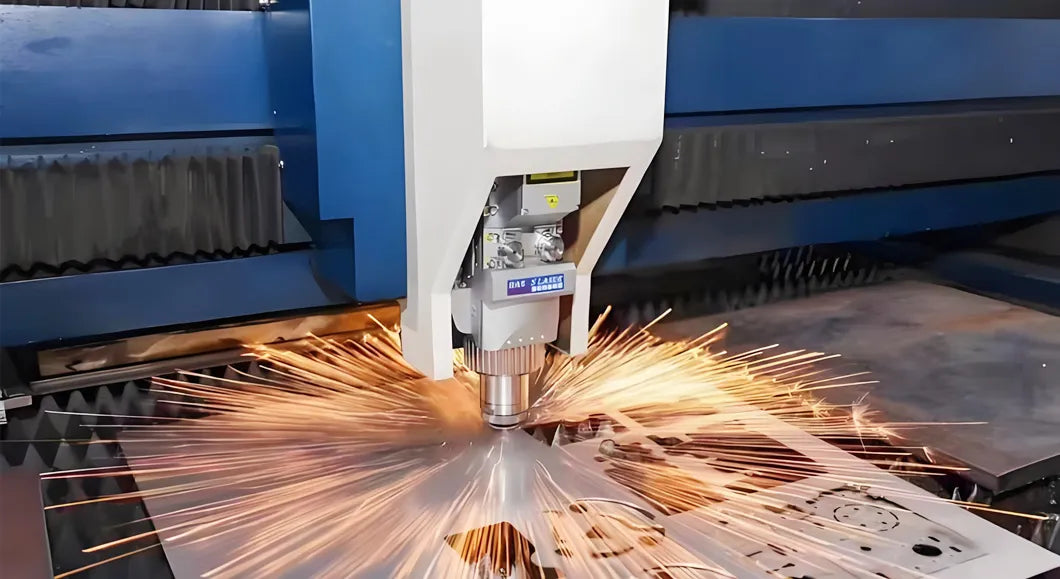

1. Fiber Laser Cutting

Fiber laser cutting can do both plane cutting and bevel cutting, and the edges are neat and smooth. It is suitable for high-precision cutting of metal plates, etc. At the same time, with the addition of a robotic arm, it can perform three-dimensional cutting instead of the originally imported five-axis laser. Compared with ordinary carbon dioxide laser cutting machines, it saves more space and gas consumption, and has a high photoelectric conversion rate. It is a new energy-saving and environmentally friendly product, and it is also one of the new technology products.

2. CO2 Laser Cutting

CO2 laser cutting is suitable for special parts that require uniform cutting, advertising, decoration and other service industries, stainless steel with a thickness of no more than three millimeters and non-metallic materials with a thickness of no more than twenty millimeters. Another type is to cut workpieces with complex contours but small quantities, which is used to save the cost and cycle of manufacturing molds.

3. Fiber Laser Cutting Machine VS. CO2 Laser Cutting Machine

3.1 Beam Quality

The focus spot of fiber laser cutting machine is smaller, the cutting line is finer, the working efficiency is higher, and the processing quality is better.

Fiber Laser Cutting

3.2 Cutting Speed

The fiber laser cutting machine is twice that of the CO2 laser cutting machine with the same power.

3.3 Stability

The fiber laser cutting machine adopts imported fiber laser, with stable performance and the service life of key components can reach 100,000 hours.

3.4 Electro-optical Conversion Efficiency

The photoelectric conversion rate of traditional CO2 laser cutting machine is only 8%-10%, which is obviously dwarfed by fiber cutting, because the photoelectric conversion rate of fiber laser cutting machine can reach 30%, which is 3 times higher than that of CO2 laser cutting machine, energy saving and environmental protection. For factories with long-term metal processing needs, even if there is only a 1% improvement, long-term use can save a lot of costs.

3.5 Use Cost

The power consumption of fiber laser cutting machine is only 20-30% of that of similar CO2 laser cutting machine.

3.6 Maintenance Cost

The initial investment is relatively high, but the maintenance cost is low. The fiber laser cutting machine is a laser-free working gas. There are basically no consumables in its working process. It uses fiber transmission and does not require reflective lenses. It can also work normally in relatively harsh environments and has high resistance to adverse factors such as dust and vibration. It can save a lot of maintenance costs, while the maintenance cost of the usual CO2 laser cutting machine is relatively high, because its front and rear mirrors are expensive, there are many consumable parts, and the life of the turbine bearing is very short. Once a problem occurs and needs to be replaced, it will face a high cost.

3.7 Flexible Light Guide Effect

Small size, compact structure, easy to flexible processing requirements. The fiber laser cutting machine adopts a unique design of German technology, especially the inner cavity, to ensure stable operation of the system and constant and lasting power. The cutting gap is uniform and consistent, and the calibration and maintenance are convenient.

3.8 Technical Application

CO2 laser cutting machine is not only complex in structure and high in maintenance cost, but also has a large beam divergence during processing, which is not suitable for large-format processing. And because its cutting seam is relatively thin, the speed will be relatively slow when processing thick plates. Such technical effects and efficiency are not conducive to long-term processing in the factory. On the contrary, the laser of the fiber laser cutting machine has the advantages of miniaturization, high brightness and high conversion rate. When processing on thin plates, the fiber laser cutting machine with the same power is 2-3 times faster than the CO2 cutting speed!

Summary

Fiber laser cutting and CO2 laser cutting each have their own advantages and disadvantages. The selection of suitable laser cutting technology should be based on the specific application, material type, cutting requirements and economic factors. Fiber laser cutting is more suitable for metal processing, while CO2 laser cutting is more suitable for non-metallic materials. According to your specific needs, choosing the right laser cutting method for the material will help improve production efficiency and cutting quality.

If you have related needs, please contact us immediately and we will provide you with the best offer!

- Choosing a selection results in a full page refresh.