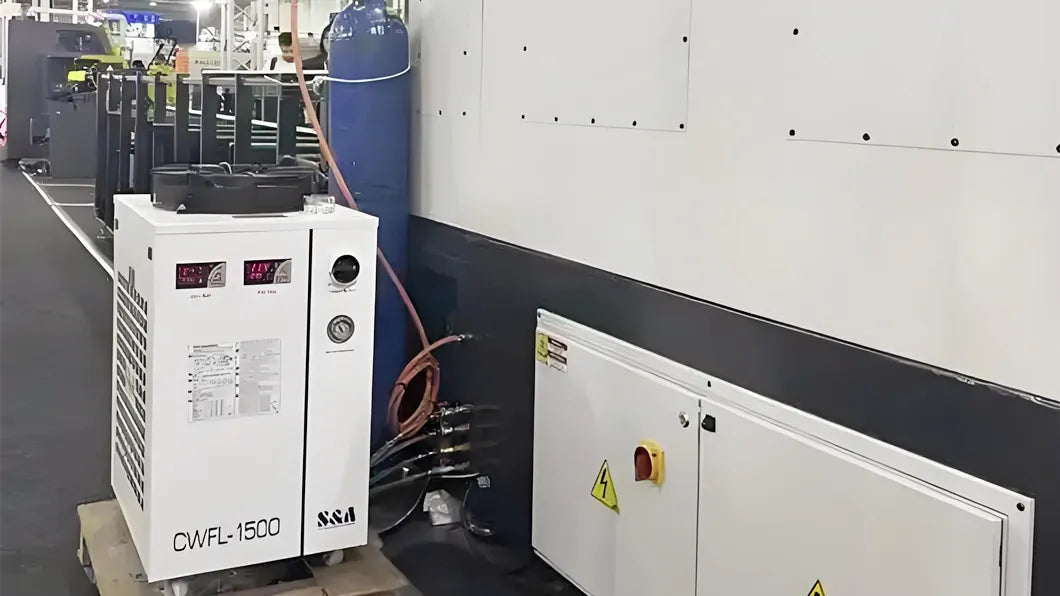

Laser Chiller Repair Guide

The function of the laser chiller is not only to cool the laser, but also the cooling of the cutting head mainly depends on the chiller. This article will talk about the "blood vessels" of fiber laser processing equipment - the laser chiller repair.

Why Does Laser Equipment Need a Chiller?

The main working principle of laser equipment is to convert electrical energy into light energy. Because the conversion between energy and energy is not 100%, while part of the electrical energy is converted into light energy, the other part is converted into heat energy; in addition, the operation of the equipment and the friction of the metal will also cause the laser cutting head to generate a lot of heat energy. The heat energy remains in the laser and the cutting head, which may affect the processing effect or damage the components inside. Everyone knows that the cost of lasers and cutting heads is high, and the repair and replacement price after damage is also very expensive. Therefore, using water cooling to dissipate heat can reduce the loss rate of equipment and reduce maintenance costs.

Laser Chiller Repair and Analysis

- The laser chiller is not powered on when it is turned on

There may be two reasons for this fault:

The power cord is not plugged in. Solution: Check whether the power interface and the power plug are plugged in and in good contact;

The fuse is blown. Solution: Replace the fuse in the power interface behind the machine.

- When using the laser chiller, a flow alarm appears, and the outlet and inlet are directly connected with a water pipe, and there is no water flow. What's going on?

Laser Chiller Repair Guide

Cause of failure: The reason for this situation may be that the water level in the water tank is too low.

Solution: Add water and check for pipe leakage.

- When the laser chiller is connected to the equipment, the flow alarm (the red light on the panel is on), but the outlet and inlet are directly connected with a water pipe.

Cause of failure: The water level in the water tank is too low; the water circulation pipeline is disconnected, blocked or bent and deformed; the water pump is damaged.

Solution: Add water to above the minimum liquid level line; check the water circulation pipeline; replace the water pump. Check the circulating water pipeline. If the water pipe used by the customer is too long or too thin, the flow alarm will also appear if the flow rate is lower than 3L/min.

- Sensor failure

When the chiller has a sensor fault code, it may be that the temperature sensor or screen is abnormal. At this time, we need to replace the temperature sensor or screen to solve the problem.

Summary

Laser chiller repair is essential for efficient and stable operation of the laser system. Regular maintenance and timely troubleshooting will help improve the chiller's operating efficiency and extend the life of the equipment.

If you have related needs, please contact us immediately and we will provide you with the best offer!

- Choosing a selection results in a full page refresh.