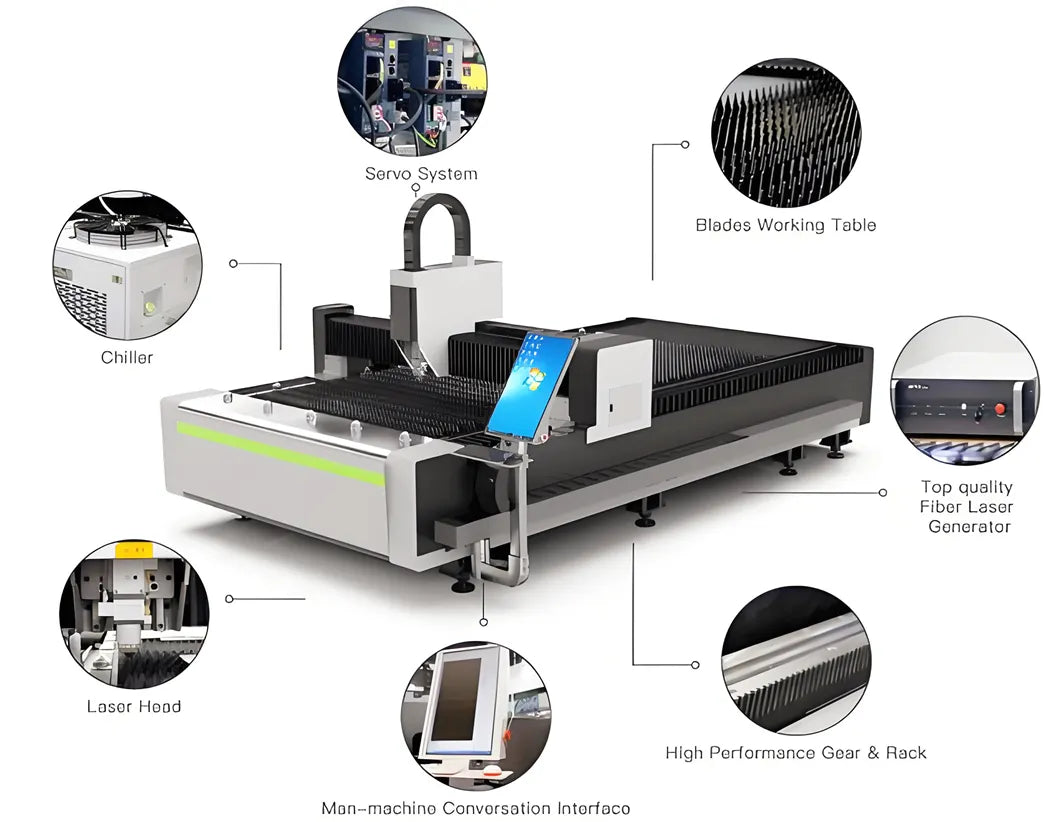

What are the Main Fiber Laser Machine Parts Components?

Fiber laser cutting machines are highly efficient cutting equipment commonly used in industry, mainly composed of multiple components. The following are the main fiber laser machine parts and their functions.

1. Laser generator

This is one of the core components of the laser cutting machine, which is used to generate the laser beam. Depending on the type, the laser generator can be a CO2 laser, a fiber laser, or a solid laser. Each laser has different advantages and disadvantages and is suitable for cutting different materials.

2. Optical system

Includes lenses and lenses, which are used to focus the laser beam on the cutting material. These optical components need to be cleaned and maintained regularly to ensure cutting quality and efficiency.

3. Cutting head

The cutting head is responsible for guiding the focused laser beam to the surface of the cutting material, usually just on the surface of the material. There is usually a gas blower in the cutting head to provide auxiliary gas (such as oxygen, nitrogen) during cutting to enhance the cutting effect and remove molten materials.

4. Motion System

One of the fiber laser machine parts, generally composed of servo motors, linear guides and rolling bearings, it is used to control the precise movement of the cutting head in the X and Y axes (some high-end models may also support the Z axis). The accuracy and speed of this system directly affect the cutting quality and efficiency.

5. Control System

Includes computer hardware and corresponding software for controlling the operation of the laser cutting machine. This usually involves designing cutting patterns, setting cutting parameters, and monitoring the operating status of the equipment.

6. Base/frame

Provides structural support for the laser cutting machine to ensure stability and static support. The base is usually also designed to support the material during the cutting process.

7. Gas supply system

Used to provide auxiliary gases (such as oxygen, nitrogen, air, etc.) required for cutting to support the cutting process and remove slag generated during the cutting process.

8. Cooling system

The laser generator and cutting head generate heat during operation, so a cooling system is required to maintain the operating temperature, which usually includes water cooling and air cooling systems.

9. Safety protection device

Includes protective covers, laser monitoring systems, etc., to protect operators and equipment from laser radiation and other potential hazards.

10. Smoke/exhaust system

Smoke and gas are generated during the cutting process, so the smoke exhaust system helps to exhaust these exhaust gases and smoke from the working area to keep the working environment clean and safe.

Summary

These fiber laser machine parts work together to enable the laser cutting machine to efficiently and accurately complete the material cutting work and ensure the safety and reliability of operation. Different types and brands of laser cutting machines may differ in design, but the above components are the basic components of most laser cutting machines.

If you have related needs, please contact us immediately and we will provide you with the best offer!

- Choosing a selection results in a full page refresh.