What is Laser Welding With Filler Wire ?

Laser welding with filler wire is a welding technique that combines laser welding with the addition of a filler material, usually in the form of a wire, to help create a stronger joint between two pieces of metal. This method is particularly useful in applications where the materials being joined are of different thicknesses or where additional material is needed to fill gaps or enhance the weld.

Key Features and Process:

Laser Source: The process uses a focused laser beam as the primary heat source. The laser can be either continuous wave (CW) or pulsed, depending on the application.

Filler Wire: A filler wire is fed into the weld pool created by the laser beam. The filler wire can be made of the same material as the parent metal or a compatible alloy to ensure good bonding and the desired mechanical properties.

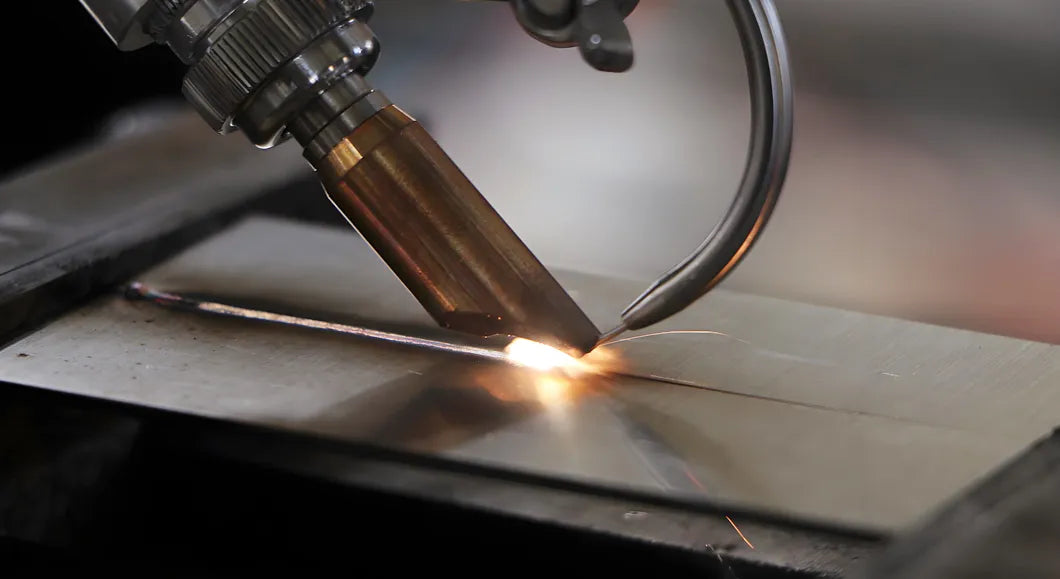

Welding Procedure: The laser beam is focused on the joint area of the two parent metals, creating a molten weld pool.

As the laser moves along the joint, a filler wire is simultaneously introduced into the weld pool. The heat generated by the laser melts the filler wire, causing it to blend with the base materials and form a strong bond after cooling.

The process is typically performed in a controlled atmosphere to prevent contamination and oxidation.

Applications:

Due to its versatility and high precision,laser welding with filler wire is commonly used in a variety of industries, including:

- Automotive manufacturing (body components, chassis components)

- Aerospace (aircraft components)

- Biomedical devices (surgical instruments, implants)

- Electronics (housings and connections)

Summary

Overall, laser welding with filler wire is an efficient and effective joining process that can be tailored to specific requirements in demanding applications. It combines the advantages of laser welding technology with the additional strength and versatility provided by filler materials, making it a preferred choice in many advanced manufacturing environments.

If you have related needs, please contact us immediately and we will provide you with the best offer!

- Choosing a selection results in a full page refresh.