Professional Service

Exclusive Customization

Industry-Leading Innovation

Reliable manufacturer

Ball Screw Features

√Positioning accuracy up to micron level

√Advanced ball design, low friction

√High load capacity

√Strong wear resistance

√Smooth operation

√Provide a variety of specifications and sizes

√Strong compatibility

√Easy to install

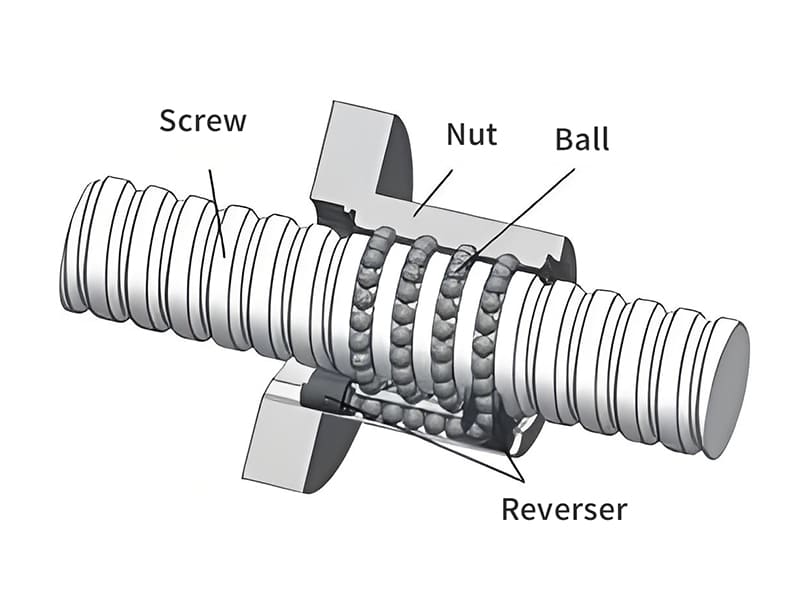

Servo ball screw FFA series operating principle

Converts rotary motion into linear motion, based on the interaction of balls and threads

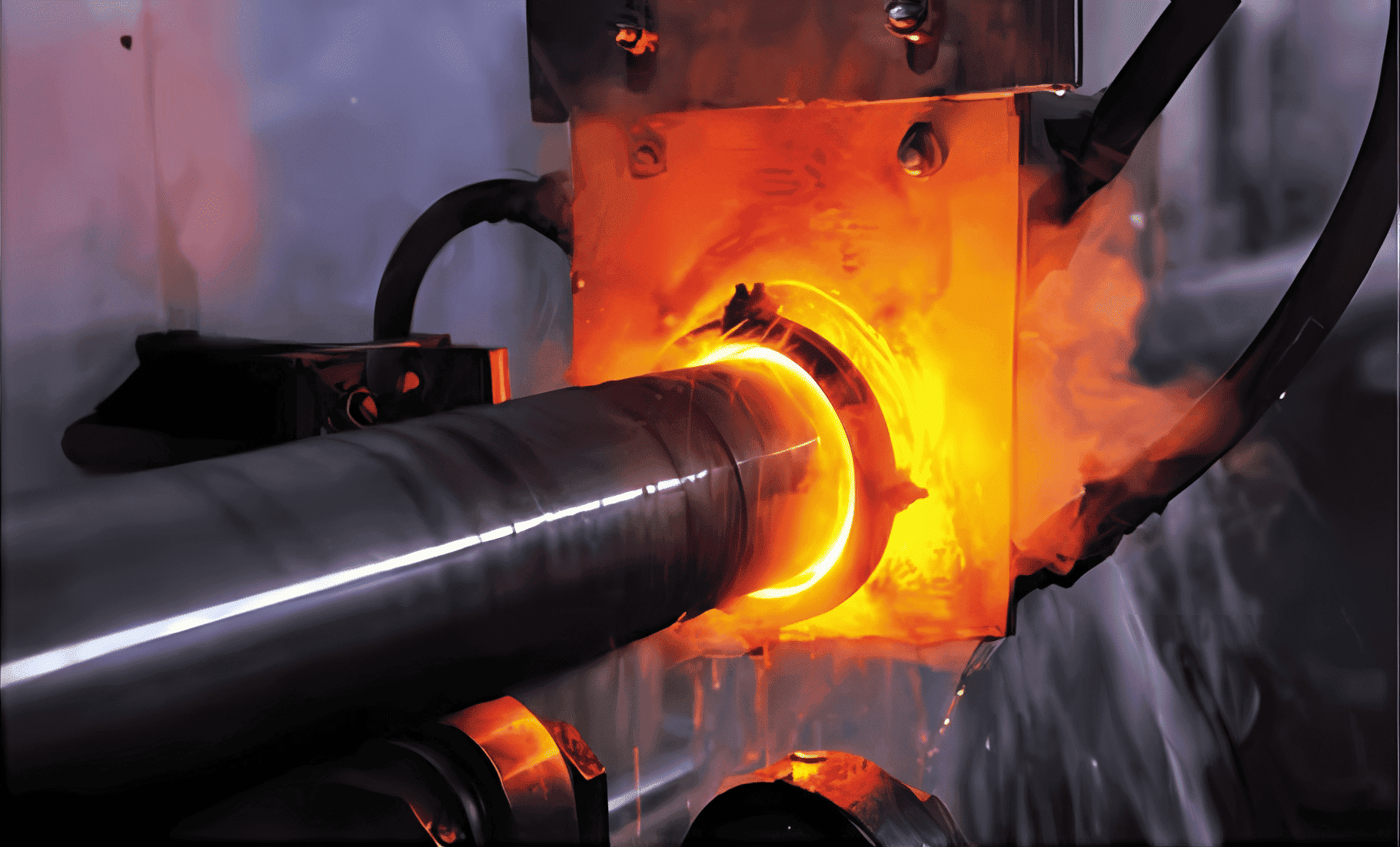

Heat Treatment Hardness

| Part name | Heat treatment | Hardness (HRC) |

| Screw | Induction heating, quenching | 58-62 |

| Nut | Carburizing, quenching, tempering | 60-62 |

| Ball | / | 62-65 |

Advantages of Rolled Ball Screw FFA

- Long life, cold extrusion makes the surface structure of the servo ball screw thread more dense, improves wear resistance and life.

- Good finish, compact surface structure, high finish. This makes the rolled ball screw have less friction during operation, reduces energy loss, and improves transmission efficiency.

- Notch sensitivity is reduced, the raw material fiber is elongated and thinned without cutting, and the grain refinement makes the incision relatively complete.

- Excellent dimensional accuracy, after die extrusion forming, the size of each workpiece is basically the same, and the screws and nuts are interchangeable.

- Reasonable manufacturing process, the workpiece length is not limited by the length of the machine tool, and the grinding of ball screws with larger long diameters can be realized, which is suitable for large-scale automated production, reducing costs and shortening production cycles.

Routine examination

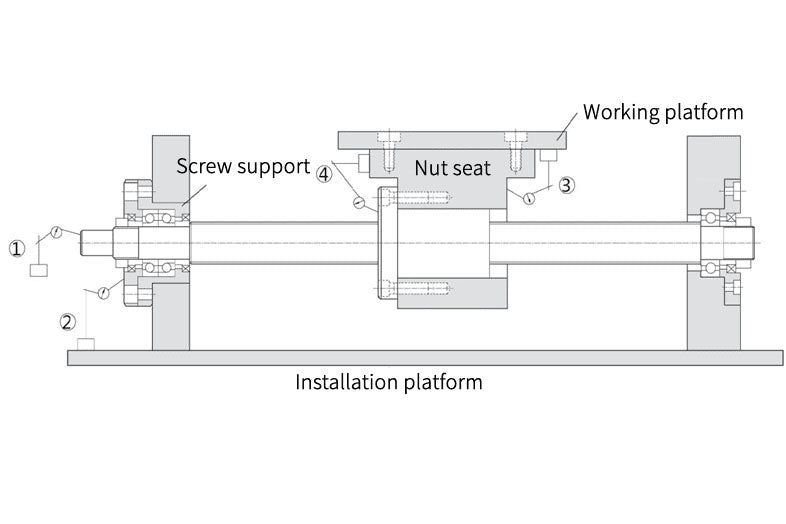

- Check the amount of runout of the shaft head;

- Check the amount of movement of the rolled ball screw support and the mounting platform;

- Check the relative amount of movement between the working platform and the nut seat;

- Check the relative amount of movement between the nut seat and the nut flange.

Advanced processing technology

Quenching

The heated FFA series ball screw is quickly immersed in a quenching medium (such as oil or water) to cool it quickly.

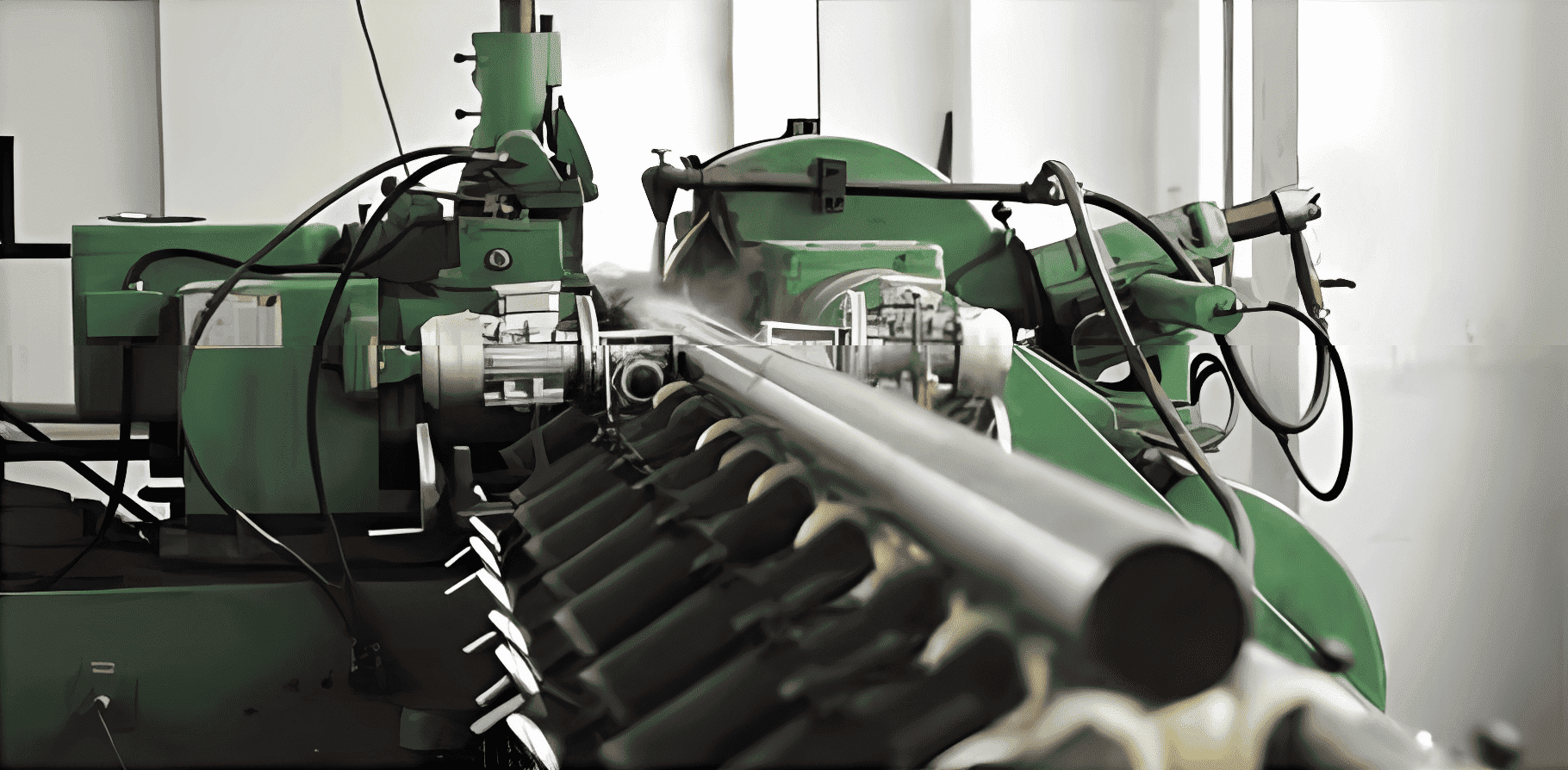

Straightening

Based on the measurement results, adjust the support points or fixed points of the rolled ball screw to gradually correct its straightness.

Finished product inspection

Check the roundness of the servo ball screw to ensure that it does not produce significant deviations when rotating.

Recommended for You

- Choosing a selection results in a full page refresh.