| Focal length | 100 mm / 160 mm / 254 mm |

| Working distance | 50 mm / 100 mm |

| Spot diameter | 20 μm / 30 μm / 50 μm |

| Transmittance | ≥ 95% |

| Temperature range | -10°C to 60°C |

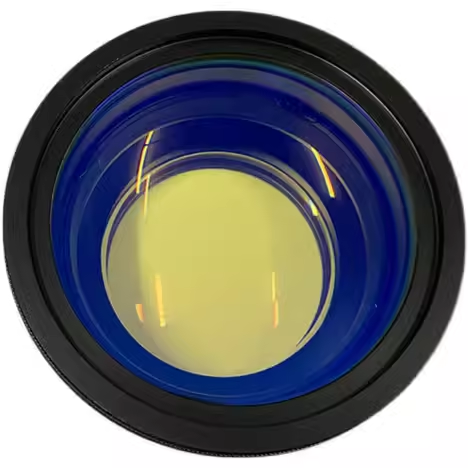

| Materials | Optical glass / Low diffusion coating |

High-precision marking

The field lens can provide a smaller spot diameter, ensuring high-precision marking on a variety of materials.

High-quality materials

Made of high-quality optical materials to ensure long-term durability.

Strong durability

Precise optical design improves the accuracy of laser focus.

Wide applicability

Applicable to a variety of materials, can meet the marking needs of different industries, and have high flexibility.

High-quality manufacturing materials and coatings

High-quality manufacturing materials and coatings ensure the durability and environmental resistance of the field lens, maintaining performance and life even under high load or harsh environments.

Replacement precautions

- Clean working environment

Before replacing the field lens, ensure that the working environment is clean to avoid dust and impurities entering the interior of the device and affecting the performance of the new lens.

- Use appropriate tools

Use the tools and equipment recommended by the manufacturer for replacement to ensure the accuracy and safety of the operation.

- Handle the field lens with care

Field lenses are usually very delicate and easy to scratch or damage. Wear gloves when handling, avoid direct contact with the mirror surface with your hands, and use lens clamps or special tools.

- Check the new lens

Before installing the new field lens, check it for scratches, dirt or other defects to ensure that it is in good condition.

- Correct installation

Ensure that the new field lens is installed correctly according to the manufacturer's instructions, paying attention to the direction and position of the lens to avoid optical path deviation.

- Adjust the focus

After replacing the field lens, it may be necessary to readjust the focus and spot settings to ensure the best performance of the laser marking machine.

7% Discount for a Limited Time!

Looking for field lens for fiber laser marking machines in bulk? Get exclusive discounts with us!

How to maintain the field lens

Regular cleaning

- Gently wipe the mirror surface with a dedicated optical lens cleaning paper or microfiber cloth. Avoid using any rough materials that may scratch the mirror surface.

- A residue-free optical cleaner such as isopropyl alcohol (IPA) can be used to gently wipe the mirror surface to remove grease and other stubborn stains.

- Before and after cleaning, the mirror surface should be inspected for scratches, cracks or other damage.

Proper storage

- When the lens is not in use, it should be stored in a dry, clean environment with a suitable temperature. It can be stored with a dust cover or a dedicated lens box.

- Avoid exposing the lens to extreme temperature or humidity conditions, which may cause damage to the lens material or degradation of optical performance.

Regular inspection and calibration

- Regularly check the focus and optical quality of the lens to ensure that there is no drift or degradation. If problems are found, they should be adjusted or replaced in time.

- For high-precision applications, regular professional optical calibration is recommended to maintain optimal performance.

FAQ

Can I order samples?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

How is the delivery time?

The delivery time varies from product to product. Please refer to the specific product for reference.

How do you ship and how soon can I receive the goods?

We usually ship by DHL, EMS, TNT, and you can also choose the shipping method you want. It usually takes 3-10 working days to each country. We will confirm the shipping method with you before shipping.

How do I order your products?

Tell us your application and requirements, including wavelength and power.

Recommended for You

Interested in a large quantity? Contact us to enjoy volume discounts!

- Choosing a selection results in a full page refresh.