Team Service

Extensive Product Range

Easy to Operate

After-sales Support

Features

- This welding head has strong advantages in medium-thick plate welding and large-piece welding applications. It is a cost-effective and efficient welding head.

- The internal structure of the welding head is completely sealed to prevent dust contamination of the optical part.

- Equipped with air curtain components to reduce contamination of lenses by welding smoke and splash residue.

- The focus adjustment adopts a cam structure, which makes the adjustment precise and convenient. The protective lens adopts a drawer-type structure, which is easy to replace.

- CCD components can be configured according to customer requirements, and can be equipped with coaxial.

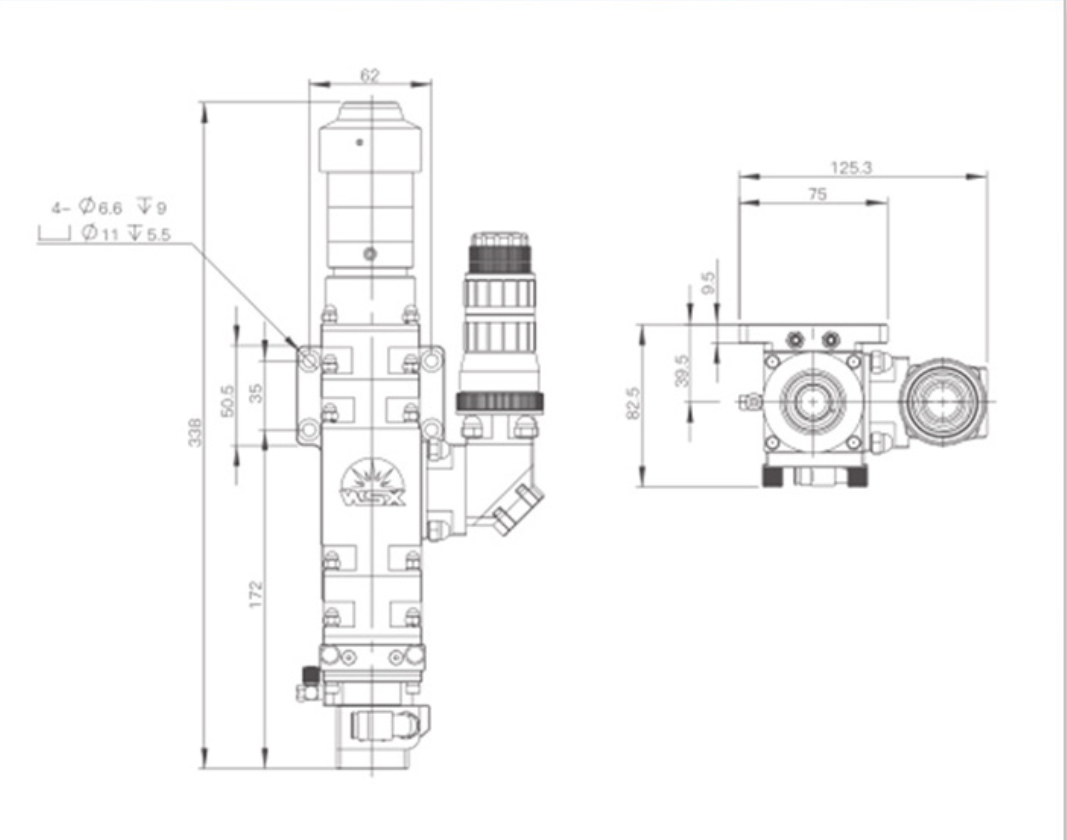

Specifications

Model: WSX ND26

Maximum power:2000W

Collimation focal length:75mm/100mm

Focus focal length:150mm/200mm

Weight:3.2kg

Effective clear aperture:Ø027mm

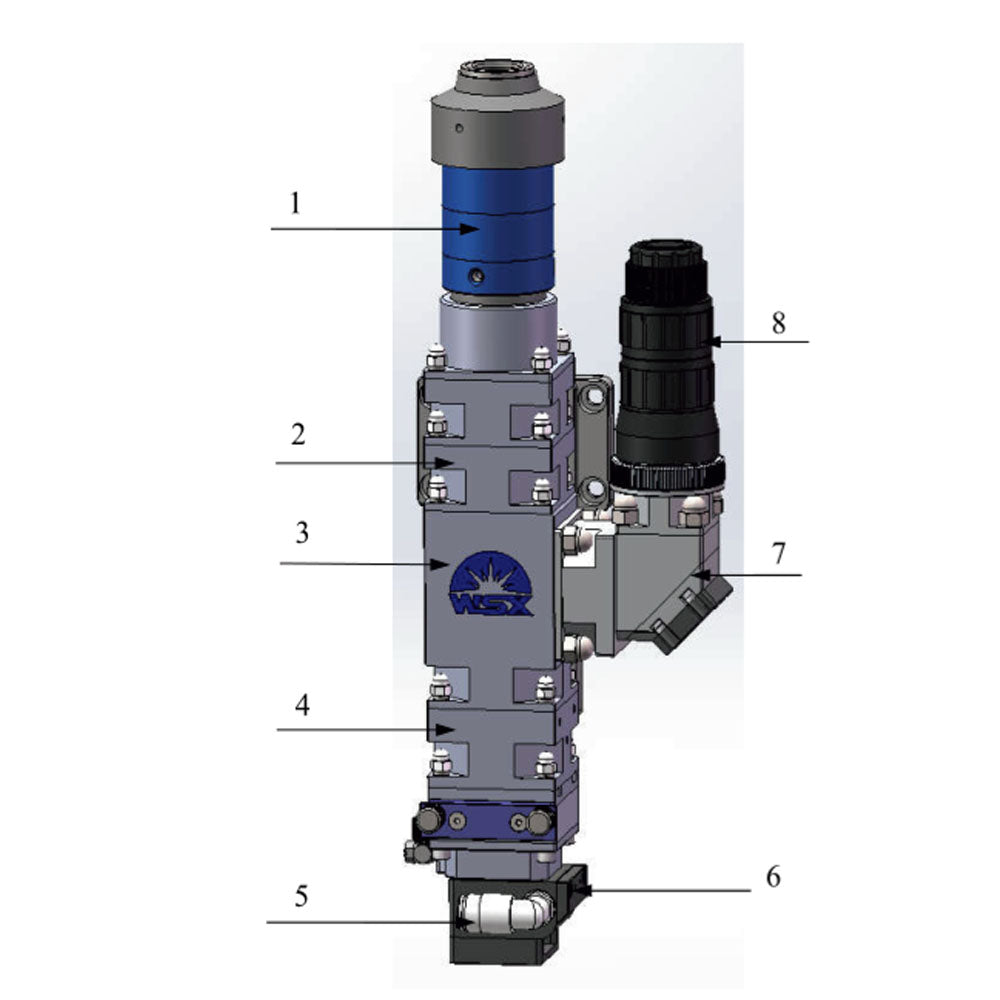

Structure

1.QBH components

2.Beam expansion component

3.focus component

4.Cross-blown air curtain components

5.Air wand assembly

6.Reflective component

7.CCD components

8.Splitter component

Get 10% Off On First Purchase!

Offer valid for first-time customers only. Contact for details.

Product display

FAQ

How long is the service life of the laser head?

The lifespan of a laser welding head can vary due to factors like design, usage frequency, maintenance, and environment. Here's an overview:

1.Quality and design: Well-designed, high-quality laser welding heads tend to last longer. Those made with durable materials and advanced technology can handle heavier workloads and harsher conditions.

2.Maintenance: Regular upkeep is essential. This includes cleaning optical components, aligning lenses, and replacing worn-out parts.

3.Frequency of use: Heads used often may wear out faster. Continuous, intense use can speed up aging.

4.Operating conditions: Factors like temperature, humidity, dust, and vibration can impact lifespan. Harsh conditions typically shorten it.

In general, lifespans range from several years to a decade. Some high-quality industrial heads can last over 10 years with proper care. To maximize lifespan, follow manufacturer guidelines closely

How to clean the laser head?

Preparation:

- Power Off: Ensure the laser equipment is completely powered off before cleaning to avoid accidental startup and electric shock.

- Use the Right Tools: Gather lint-free cloths, optical cleaning paper, optical cleaning solution (like high-purity isopropyl alcohol), an air blower for dust, and soft brushes or cotton swabs if needed.

Cleaning Steps:

External Cleaning:

- Gently blow away dust and particles from the welding head's exterior using an air blower.

- Lightly wipe the outer casing with a lint-free cloth, avoiding hard tools that could scratch it.

Cleaning Optical Components:

- Carefully remove optical components like lenses and mirrors, if possible.

- Use optical cleaning paper with a bit of cleaning solution to gently wipe the surfaces in a spiral motion from the center outwards.

- For hard-to-reach areas, use cotton swabs with caution.

Reinspection and Assembly:

- After cleaning, thoroughly check optical components for stains, spots, or scratches.

- Reinstall components securely to prevent movement during operation.

Additional Tips:

- Avoid touching optical surfaces with bare hands to prevent oil stains.

- Do not use harsh solvents or cleaners that could damage the surfaces.

Following these steps ensures effective cleaning of the laser welding head, maintaining equipment performance and longevity.

About TSC

TSCbro is a globally leading supplier of industrial laser equipment accessories, headquartered in China. Since its inception, we have been dedicated to providing the most advanced and reliable products and solutions to customers in the industrial field, becoming a standout in the industry.

- Choosing a selection results in a full page refresh.