Specifications of Laser Focus Lens

| Lens diameter | 20 mm / 25 mm / 30 mm | Focal length | 50 mm / 100 mm / 150 mm |

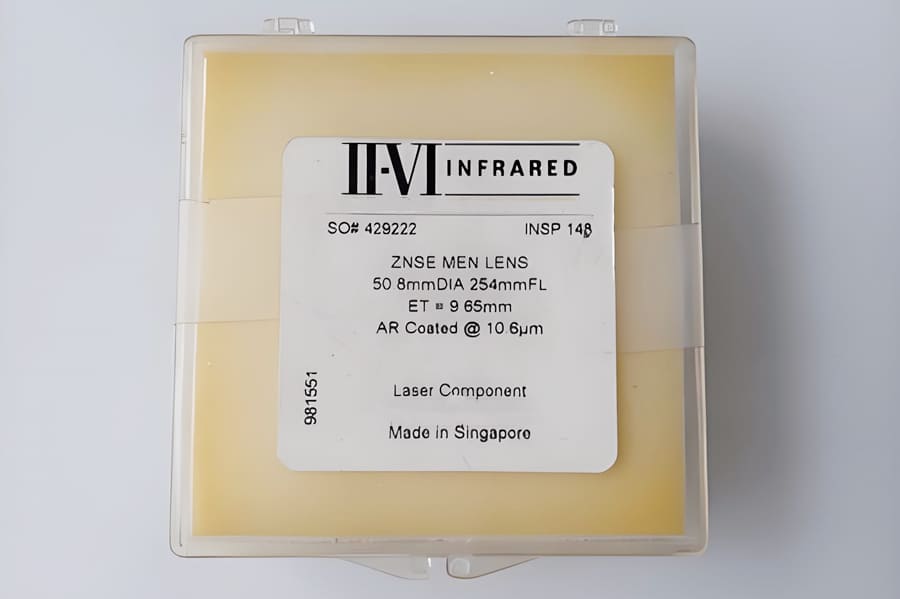

| Material | Optical glass / Silicate / ZnSe | Coating type | Single-layer coating / Multi-layer coating |

| Transmittance | ≥ 95% | Operating temperature | -10°C to 60°C |

| Applicable wavelength | 1064 nm | Beam quality | M² < 1.2 |

| Maximum power | 500 W / 1000 W / 2000 W | Applications | Metal cutting / Non-metal cutting / Marking |

Laser Cutter Lenses Advantages

High-precision cutting

The laser focus lens can focus the laser beam to a very small point, thus achieving high-precision cutting and processing, which is suitable for complex shapes and delicate workpieces.

Excellent beam quality

The high-quality focusing lens can maintain the quality of the laser beam, ensure the energy concentration during the cutting process, and improve the cutting efficiency and effect.

Wide range of application

The laser focusing lens is suitable for a variety of materials, including metals (such as stainless steel, aluminum, copper) and non-metals (such as plastics, wood, acrylic), meeting different industrial needs.

Strong durability

The fiber laser focusing lens made of high-quality optical materials and coatings has good wear resistance and high temperature resistance, and can maintain stable performance in high-power laser cutting.

Laser Cutter Lenses Buying Guide

Wavelength

Different types of lasers (such as CO2 lasers, fiber lasers) use lenses with different wavelengths. Make sure to choose lenses that match the wavelength of your laser source.

Transmittance

Choose lenses with high transmittance (≥ 95%) to improve laser cutting efficiency and reduce energy loss.

Coating

Multi-layer coating can improve transmittance and durability, suitable for high-power and high-precision cutting needs.

Recommended for You

- Choosing a selection results in a full page refresh.